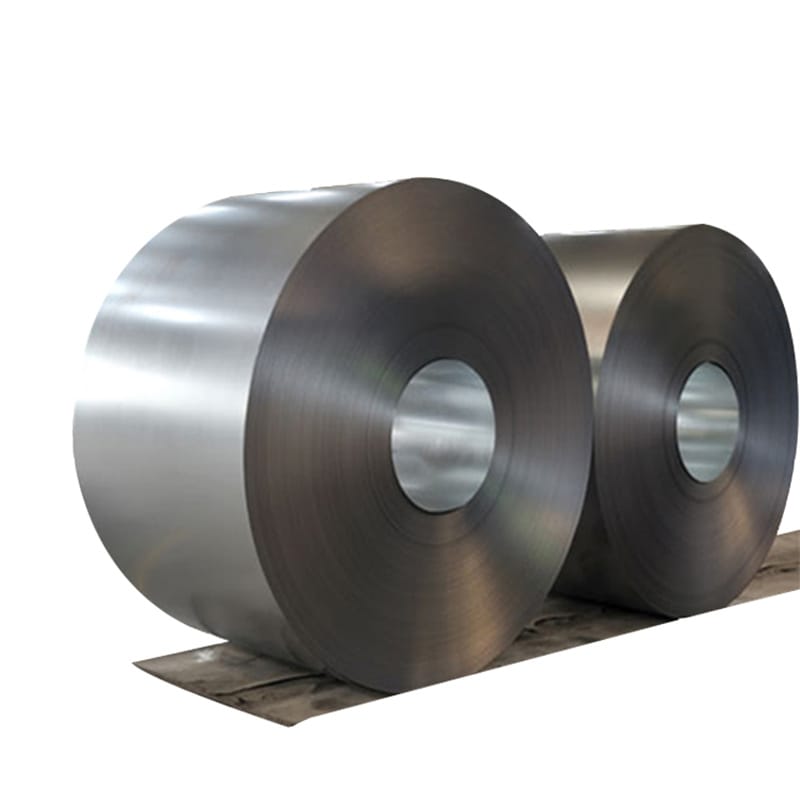

Stainless Steel Coil

Stainless steel coil is a product that is processed into a coil by hot rolling or cold rolling. It has the characteristics of high strength, corrosion resistance, high temperature resistance, etc. and is widely used in many industries.

Description

Stainless steel coil is a product that is processed into a coil by hot rolling or cold rolling. It has the characteristics of high strength, corrosion resistance, high temperature resistance, etc. and is widely used in many industries.

Classification

By material:

Austenitic stainless steel: such as 304, 316, has good corrosion resistance and processing performance.

Ferritic stainless steel: such as 430, has weak corrosion resistance, but low cost.

Martensitic stainless steel: such as 410, has high hardness and good wear resistance.

Duplex stainless steel: such as 2205, has the advantages of both austenite and ferrite, high strength and corrosion resistance.

By surface treatment:

2B surface: smooth and reflective, common in general use.

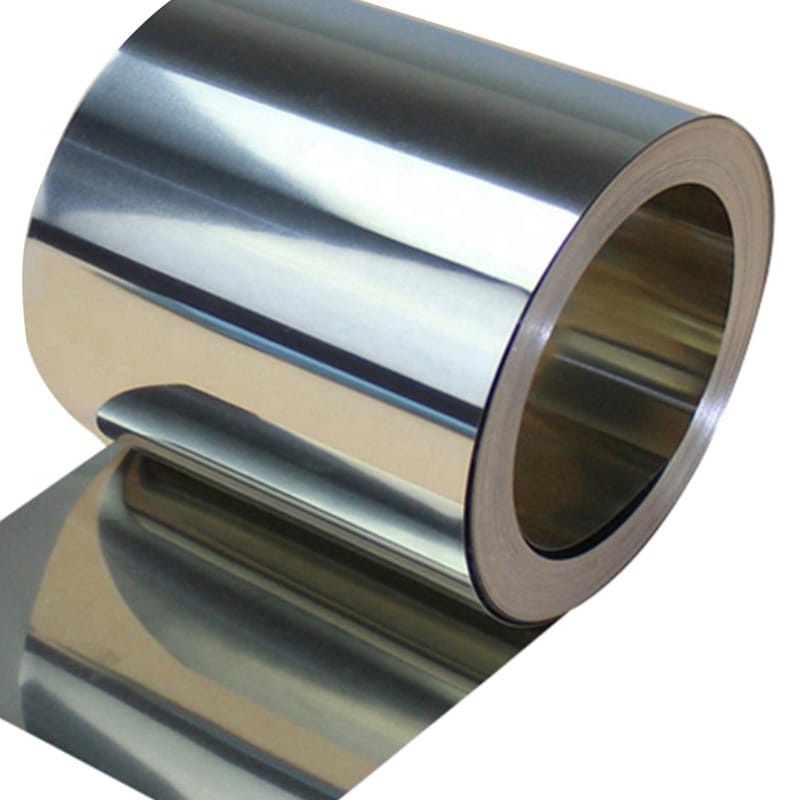

BA surface: highly bright, often used for decoration.

NO.1 surface: untreated after hot rolling, rough surface.

NO.4 surface: polished, delicate surface.

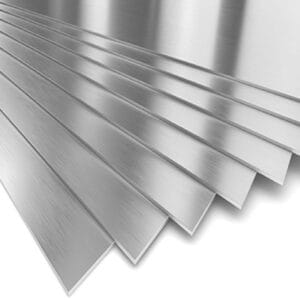

By thickness:

Thin plate coil: less than 3mm thick, suitable for precision processing.

Medium plate coil: 3-6mm thick, suitable for general industry.

Thick plate coil: Thickness greater than 6mm, suitable for heavy equipment.

Process

Hot rolling: Rolling at high temperature, high production efficiency, but rough surface, often used for thick plates.

Cold rolling: Rolling at room temperature, smooth surface, precise size, suitable for thin plates.

Annealing: Slow cooling after heating to eliminate internal stress and improve performance.

Pickling: Remove the surface oxide layer and improve corrosion resistance.

Polishing: Improve surface finish, suitable for decorative materials.

Features

Corrosion resistance: Chromium elements form an oxide film to prevent further corrosion.

High strength: Suitable for applications with high strength and wear resistance requirements.

High temperature resistance: Some stainless steels still maintain performance at high temperatures.

Easy to process: Good plasticity and toughness, suitable for a variety of processing methods.

Beautiful: Various surface treatments, suitable for decoration and construction.

Uses

Architectural decoration: Used for curtain walls, doors and windows, handrails, etc.

Kitchen equipment: Used for kitchen utensils, tableware, sinks, etc.

Medical equipment: Used for surgical instruments, medical equipment, etc.

Automobile manufacturing: used for exhaust pipes, decorative strips, etc.

Chemical equipment: used for storage tanks, pipelines, reactors, etc.

Electronic appliances: used for electronic components, home appliance housings, etc.

Stainless steel coils have become an indispensable material in modern industry due to their excellent performance and diverse applications.