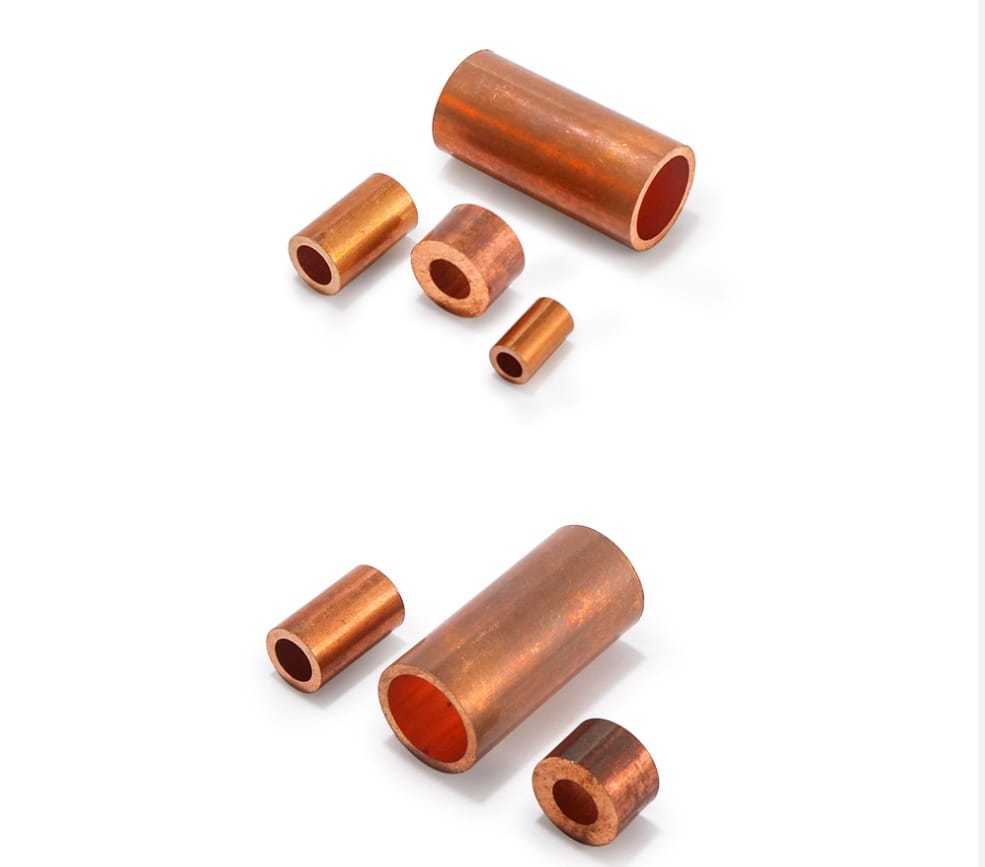

Copper Tube

Copper tubes are tubular materials made of copper or copper alloys. They have excellent thermal conductivity, electrical conductivity, corrosion resistance and machinability, and are widely used in industry, construction, refrigeration and other fields.

Description

Copper tubes are tubular materials made of copper or copper alloys. They have excellent thermal conductivity, electrical conductivity, corrosion resistance and machinability, and are widely used in industry, construction, refrigeration and other fields.

Classification

According to alloy composition:

Pure copper tubes: such as T2, T3, etc., with a purity higher than 99.9%, excellent electrical conductivity and thermal conductivity.

Copper alloy tubes: such as brass tubes (copper-zinc alloy), bronze tubes (copper-tin alloy), white copper tubes (copper-nickel alloy), etc., have different mechanical properties and uses.

By manufacturing process:

Seamless copper tubes: made by extrusion or drawing process, without welds, high strength, suitable for high-pressure environments.

Welded copper tubes: made by coil welding, with low cost and suitable for low-pressure environments.

By use:

Copper tubes for refrigeration: used for refrigeration equipment such as air conditioners and refrigerators.

Copper tubes for construction: used for water supply, heating, and gas pipelines.

Industrial copper tubes: used for heat exchangers, condensers, oil pipes, etc.

Medical copper tubes: used for medical equipment, requiring high purity and high cleanliness.

By surface treatment:

Bare copper tube: no surface treatment, direct use.

Coated copper tube: tin-plated, nickel-plated, etc. on the surface to enhance corrosion resistance or welding performance.

Process

Melting and casting: The copper ingot is melted and cast into a billet.

Extrusion or drawing: The billet is made into a tube by extrusion or drawing.

Annealing: Annealing is performed after cold processing to improve the flexibility and mechanical properties of the copper tube.

Surface treatment: plating, polishing or other treatments are performed as required.

Cutting and testing: The copper tube is cut to the required length and quality tested.

Features

Excellent thermal conductivity: suitable for manufacturing heat exchangers, radiators, etc.

Good electrical conductivity: used for electrical equipment and wires.

Corrosion resistance: good corrosion resistance in both dry and humid environments.

Easy to process: easy to bend, cut, weld, etc.

Antibacterial property: Copper has natural antibacterial properties and is suitable for medical and water supply pipelines.

Recyclability: It can be recycled many times, which is environmentally friendly and economical.

Applications

Refrigeration and air conditioning:

Used in the piping systems of refrigeration equipment such as air conditioners, refrigerators, cold storage, etc.

Construction and water supply:

Used in water supply, heating, and gas piping systems.

Copper pipes are particularly suitable for drinking water pipes due to their corrosion resistance and antibacterial properties.

Industrial manufacturing:

Used in heat exchangers, condensers, oil pipes, etc.

Copper alloy pipes are used to manufacture mechanical parts such as bearings and gears.

Electronic and electrical:

Used in the manufacture of wires and busbars for electrical equipment.

Transportation:

Used in cooling systems and hydraulic systems for automobiles, trains, and ships.

Medical and food:

Used in piping systems for medical equipment.

Used in piping systems for food processing equipment.

Summary

Copper pipes are widely used in refrigeration, construction, industry, electronics, transportation, medical care, and food due to their excellent thermal conductivity, electrical conductivity, corrosion resistance, and machinability. Copper pipes with different alloy compositions and manufacturing processes can meet diverse needs.