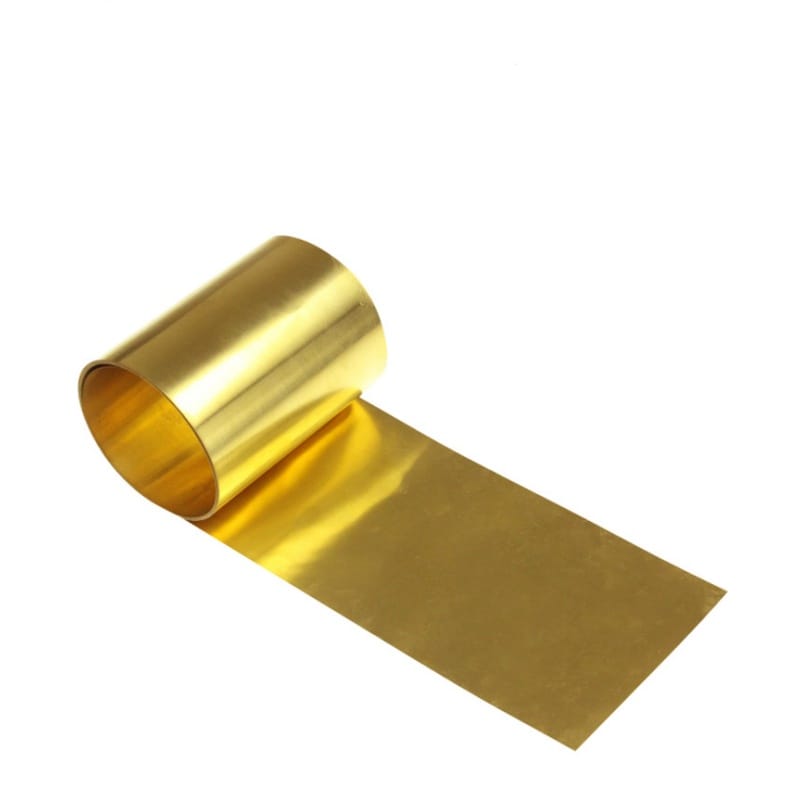

Copper Coil

Copper coil is a roll material made of copper or copper alloy through rolling process, which has excellent electrical conductivity, thermal conductivity, corrosion resistance and machinability.

Description

Copper coil is a roll material made of copper or copper alloy through rolling process, which has excellent electrical conductivity, thermal conductivity, corrosion resistance and machinability.

Classification

By alloy composition:

Pure copper coil: such as T2, T3, etc., with purity higher than 99.9% and excellent electrical conductivity.

Copper alloy coil: such as brass (copper-zinc alloy), bronze (copper-tin alloy), white copper (copper-nickel alloy), etc., with different mechanical properties and uses.

By thickness:

Thin copper coil: less than 0.2mm thick, used for electronic components, precision instruments, etc.

Medium-thick copper coil: 0.2-6mm thick, used in construction, industry and other fields.

Thick copper coil: greater than 6mm thick, used for heavy machinery, ships, etc.

By surface treatment:

Ordinary copper coil: no special treatment.

Coated copper coil: tin-plated, nickel-plated, etc. on the surface to enhance corrosion resistance or welding performance.

Oxidized copper coil: the surface is oxidized and used for special decoration or functional needs.

Process

Melting and casting: Melt the copper ingot and cast it into billet.

Hot rolling: The billet is heated and rolled into a thicker copper coil.

Cold rolling: The hot-rolled copper coil is further cold-rolled to the required thickness.

Annealing: Annealing is performed after cold rolling to improve the flexibility and mechanical properties of the copper coil.

Surface treatment: Plating, oxidation or other treatments are performed as required.

Slitting: Cut the large copper coil into the required width.

Features

Excellent conductivity: The conductivity of pure copper is second only to silver and is widely used in the electrical field.

Good thermal conductivity: Suitable for manufacturing radiators, heat exchangers, etc.

Corrosion resistance: Good corrosion resistance in a dry environment, and corrosion resistance can be enhanced after plating.

Easy to process: Easy to cut, stamp, bend, weld, etc.

Recyclability: Can be recycled multiple times, environmentally friendly and economical.

Aesthetics: Copper has a unique metallic luster and is often used in decorative materials.

Uses

Electronic and electrical:

Used in the manufacture of wires, cables, transformers, circuit boards, etc.

High-purity copper coils are used for precision electronic components.

Architectural decoration:

Used for roofs, walls, pipes, etc.

Copper alloy coils are used for decorative materials such as door handles, sculptures, etc.

Industrial manufacturing:

Used for the manufacture of heat exchangers, radiators, condensers, etc.

Copper alloy coils are used to manufacture mechanical parts such as bearings and gears.

Transportation:

Used for electrical systems and heat dissipation components of automobiles, trains, and ships.

Packaging:

Used for the manufacture of copper foil, which is used in food packaging, battery electrodes, etc.

Arts and crafts:

Used for making copperware, sculptures, jewelry, etc.

Summary

Copper coils are widely used in electronics and electrical, architectural decoration, industrial manufacturing, transportation, packaging, and art crafts due to their excellent electrical conductivity, thermal conductivity, corrosion resistance, and machinability. Copper coils with different alloy compositions and surface treatments can meet diverse needs.