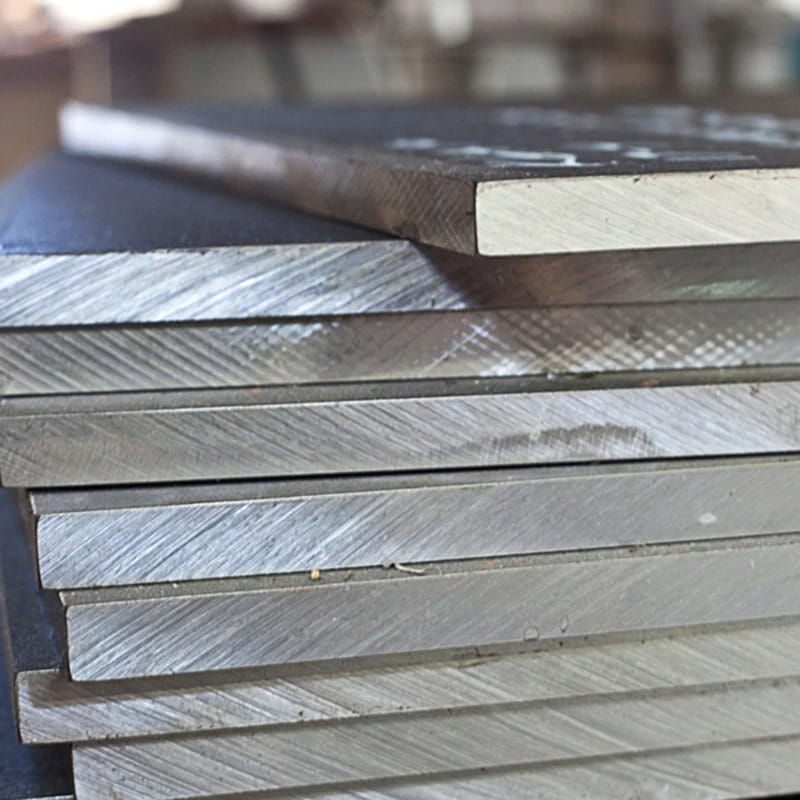

Carbon Flat Bar

Carbon steel flat bar is a long rectangular steel strip with carbon steel as the main component. Its width is greater than its thickness and its cross section is flat. The carbon content of carbon steel is usually between 0.05% and 2.0%, and contains a small amount of manganese, silicon and other elements. Flat steel is widely used in structural support, machinery manufacturing and other fields due to its regular shape and flexible processing.

Description

Carbon steel flat bar is a rectangular cross-section long steel with carbon steel as the main component. Its width is greater than its thickness and its cross-section is flat. The carbon content of carbon steel is usually between 0.05% and 2.0%, and it contains a small amount of manganese, silicon and other elements. Flat steel is widely used in structural support, machinery manufacturing and other fields due to its regular shape and flexible processing.

Classification of carbon steel flat bar by carbon content:

Low carbon flat steel (C≤0.25%): good plasticity, easy welding, used for building frames and ordinary structural parts.

Medium carbon flat steel (C=0.25%~0.60%): high strength, suitable for mechanical parts (such as shafts and gears).

High carbon flat steel (C≥0.60%): excellent hardness and wear resistance, mostly used for tools, knives, springs, etc.

According to the production process:

Hot-rolled flat steel: high temperature rolling, rough surface with oxide scale, low cost, suitable for structural use.

Cold-rolled flat steel: pickled and cold-rolled after hot rolling, smooth surface, precise size, used for precision parts.

By surface treatment:

Black flat steel: used directly without treatment after hot rolling.

Galvanized flat steel: galvanized surface to prevent rust, used outdoors or in humid environments.

Polished flat steel: polished surface, used for decoration or precision instruments.

By use:

Structural flat steel: building and bridge support.

Mechanical flat steel: manufacturing mechanical parts (such as bolts, connecting rods).

Tool flat steel: made of high carbon steel, used for knives and molds.

Production process

Hot rolling process:

Raw material preparation: the steel billet is heated to 1100~1250℃.

Rough rolling and finishing rolling: through multiple rolling passes, the target size is formed.

Cooling and coiling: coiling or cutting into strips after natural cooling.

Features: high efficiency and low cost, but the surface is rough and requires subsequent processing.

Cold rolling process:

Pickling: hot rolled flat steel is soaked in hydrochloric acid to remove oxide scale.

Cold rolling: rolling at room temperature to improve surface finish and dimensional accuracy.

Annealing: eliminate internal stress and improve plasticity (optional).

Features: smooth surface, high strength, but high cost.

Main features

Mechanical properties:

The higher the carbon content, the higher the strength and hardness, but the plasticity and weldability decrease.

Cold-rolled flat steel has higher strength than hot-rolled steel, but slightly lower toughness.

Processing performance:

Low-carbon flat steel is easy to cut, bend, and weld; high-carbon flat steel requires preheating to reduce the risk of cracking.

Corrosion resistance:

Ordinary carbon steel is easy to rust and requires surface treatment such as galvanizing, painting or spraying.

Economic efficiency:

Low raw material cost, suitable for large-scale production.

Carbon steel flat steel has become a “universal profile” in the industrial field due to its high cost-effectiveness, flexible processing and diversified specifications. From building frames to precision machinery, from home appliance housings to decoration projects, its applications cover almost all heavy industry and civil fields. When choosing, it is necessary to match the appropriate material and process according to the requirements of strength, corrosion resistance, cost, etc.