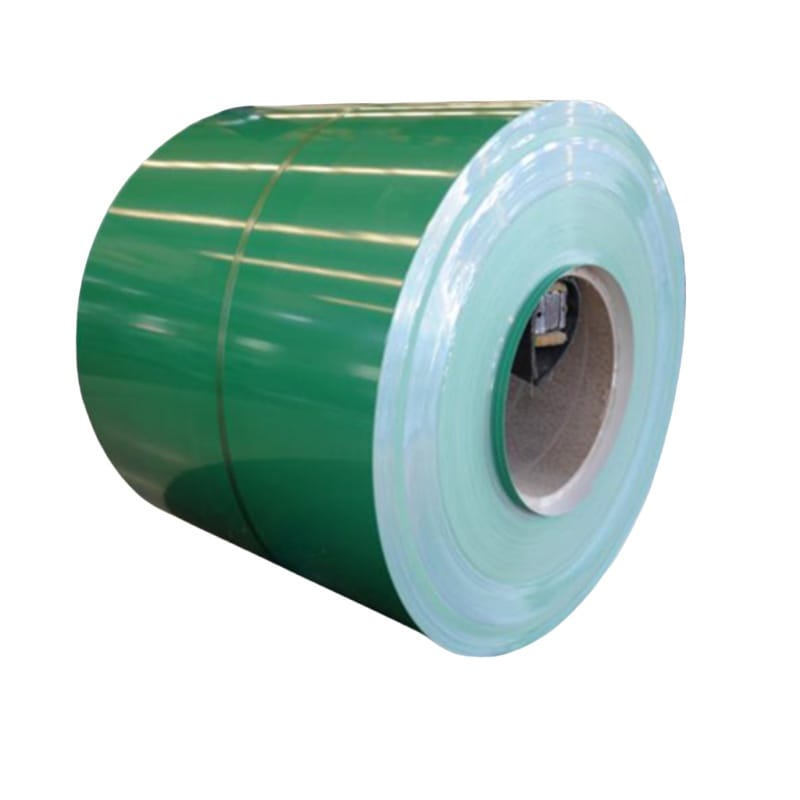

PPGI

Color-coated steel coils are products made by coating the surface of cold-rolled steel sheets, galvanized steel sheets or aluminum-zinc alloy coated steel sheets with organic coatings and then baking them.

2. Structure

Substrate: usually cold-rolled steel sheets, galvanized steel sheets or aluminum-zinc alloy coated steel sheets.

Coating: two layers on the front and one layer on the back, including primer and topcoat.

3. Features

Corrosion resistance: the coating effectively prevents corrosion of the substrate.

Decorative: a variety of colors and textures to enhance beauty.

Durability: excellent weather resistance and wear resistance.

Processability: easy to cut, bend and form.

4. Application

Construction: used for roofs, wall panels, ceilings, etc.

Home appliances: such as refrigerators and washing machine shells.

Transportation: used for automobiles and train car parts.

Furniture: office furniture, cabinets, etc.

5. Production process

Pretreatment: cleaning, phosphating, etc.

Coating: roller coating or spraying.

Baking: high temperature curing coating.

6. Advantages

Economical: Reduce maintenance costs.

Environmental protection: Some coatings are environmentally friendly and recyclable.

7. Common specifications

Thickness: 0.2mm to 1.2mm.

Width: 600mm to 1500mm.

Length: Customized according to needs.

Color-coated steel coils have become an important material in modern industry and construction due to their excellent performance and wide application.