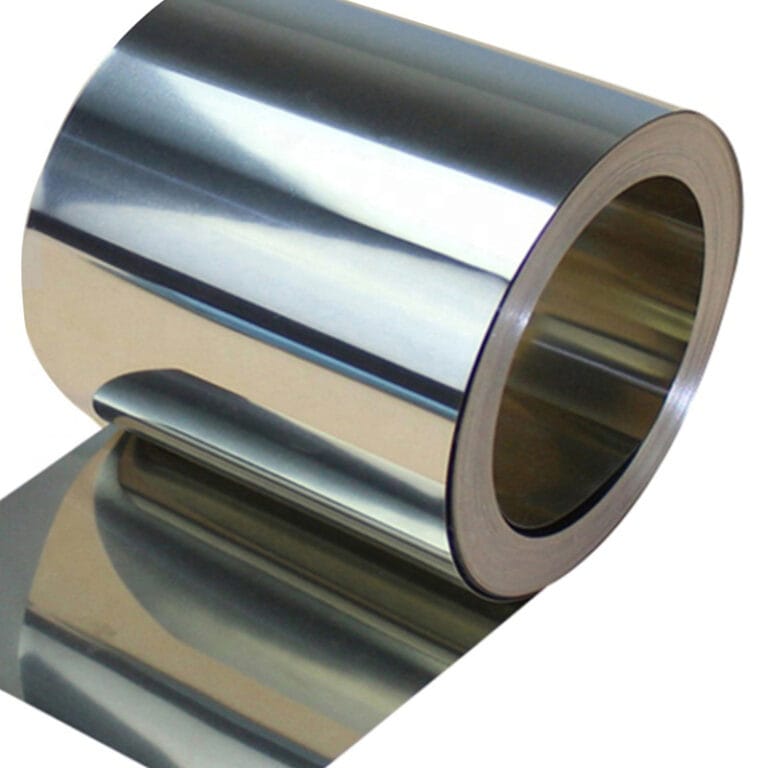

Galvanized Steel Coil

Galvanized steel coil is a steel coil with zinc coating on the surface, which is mainly used for rust prevention and extended service life. Here are its key points:

1. Definition

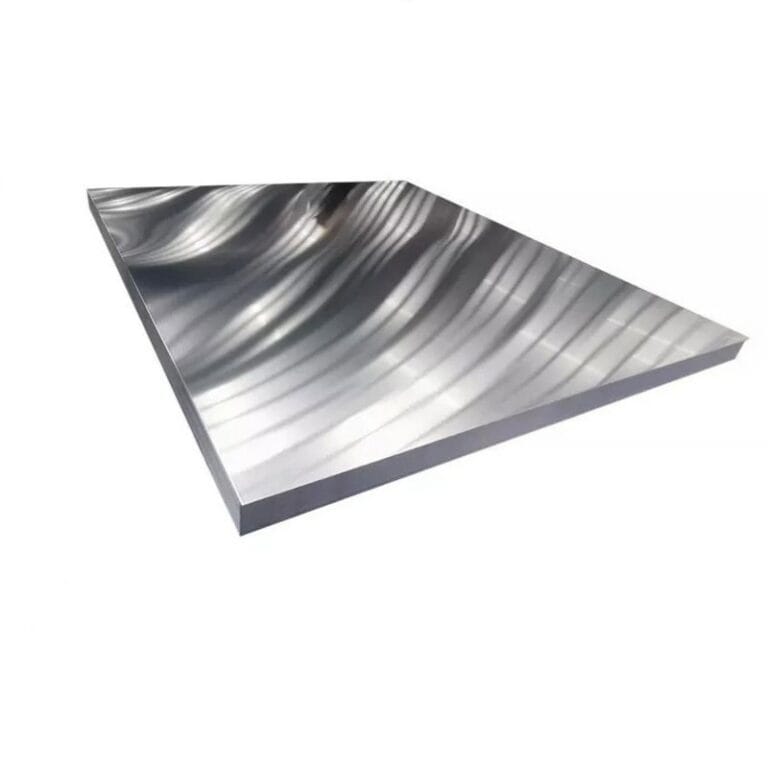

Substrate: Usually cold-rolled or hot-rolled steel coil.

Coating: The surface is coated with zinc, which is achieved by hot-dip or electroplating process.

2. Production process

Hot-dip galvanizing: The steel coil is immersed in molten zinc liquid to form a thicker zinc layer.

Electrogalvanizing: Zinc is deposited on the surface of the steel coil by electrolysis to form a thinner zinc layer.

3. Advantages

Corrosion resistance: The zinc layer effectively prevents steel from rusting.

Durability: Extends the service life of steel.

Aesthetics: The surface is smooth and suitable for a variety of applications.

4. Application areas

Architecture: Roofs, wall panels, steel structures.

Home appliances: Refrigerator, washing machine shell.

Automobile: Body parts, chassis.

Industry: Pipes, cable trays, storage equipment.

5. Common specifications

Thickness: 0.2mm to 6mm.

Width: 600mm to 2000mm.

Zinc layer weight: 60g/m² to 275g/m².

6. Standards and certifications

International standards: ASTM, JIS, EN, etc.

Certification: ISO 9001, etc.

7. Market and price

Market: widely used in global construction and manufacturing industries.

Price: affected by factors such as raw materials, zinc prices, and production processes.

Galvanized steel coils have become important materials in construction, home appliances, automobiles, and industrial fields due to their excellent anti-rust properties and wide applications.