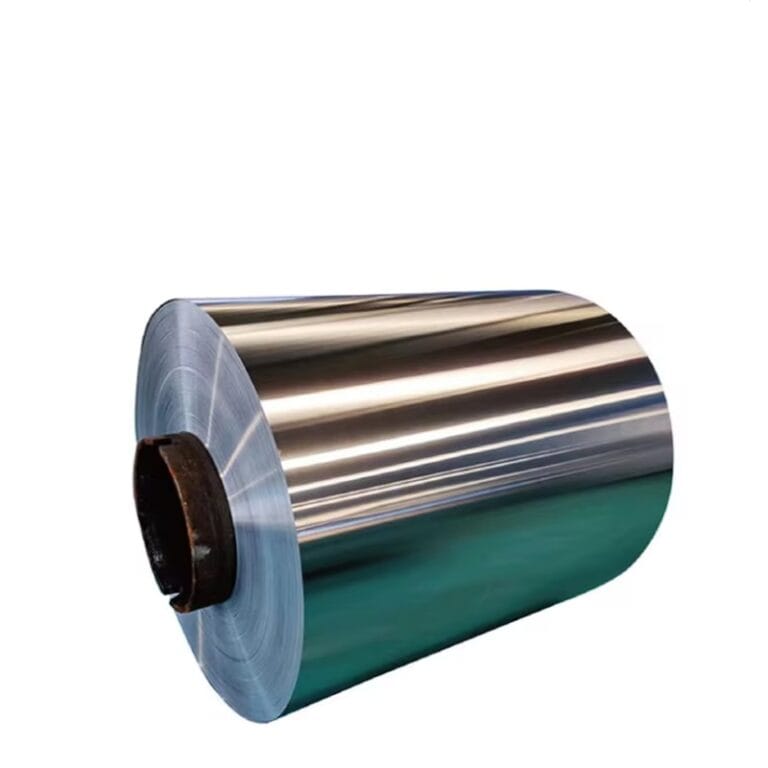

Copper Coil

Copper coil refers to a product that is made by curling copper strips or copper plates into a coil, which is convenient for storage, transportation and processing. The following is a detailed introduction to copper coils:

1. Material properties

Electronic conductivity: Copper has excellent electrical conductivity, second only to silver.

Thermal conductivity: Copper has excellent thermal conductivity and is often used in heat exchange equipment.

Corrosion resistance: Copper has good corrosion resistance in most environments.

Plasticity: Copper is easy to process into various shapes and sizes.

2. Manufacturing process

Smelting: Smelt copper ore into copper ingots.

Rolling: Process copper ingots into copper strips or copper plates through hot rolling or cold rolling.

Curling: Curl copper strips or copper plates into a coil to form copper coils.

3. Application areas

Electronic industry: used to manufacture circuit boards, connectors, cables, etc.

Construction industry: used for roofs, walls, pipes, etc.

Automotive industry: used to manufacture radiators, brake pipes, etc.

Home appliance manufacturing: used to manufacture parts for refrigerators, air conditioners and other equipment.

4. Specifications and standards

Thickness: usually 0.1mm to 3mm.

Width: Common width is 100mm to 1000mm.

Length: The length of the roll is customized according to demand, usually tens of meters to hundreds of meters.

5. Market and price

Market: The global copper roll market is mainly concentrated in China, the United States, Germany and other countries.

Price: Affected by factors such as international copper prices, market demand, and production costs, prices fluctuate greatly.

6. Environmental protection and recycling

Environmental protection: Pay attention to environmental protection and reduce pollution during the production of copper rolls.

Recycling: Copper rolls can be recycled and reused to reduce resource waste.

7. Future development trends

Technological innovation: Improve production efficiency and reduce production costs.

Green manufacturing: Promote environmentally friendly production processes and reduce environmental pollution.

Market demand: With the development of industries such as electronics, construction, and automobiles, the demand for copper rolls will continue to grow.

As an important industrial material, copper rolls are widely used and have broad prospects. With the advancement of technology and market demand, the production and application of copper rolls will continue to develop and innovate.