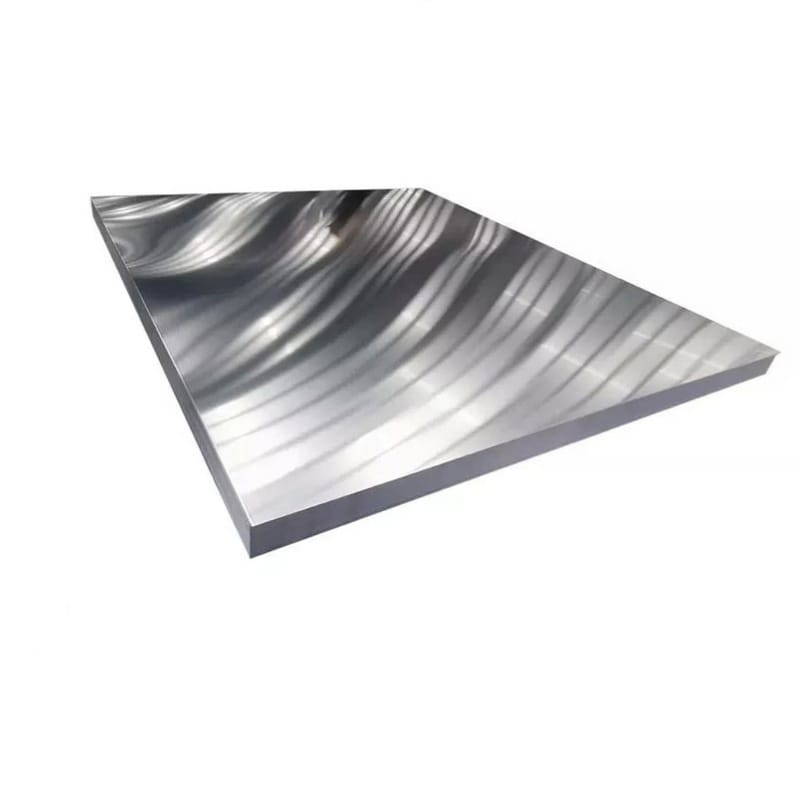

Aluminum plate

Aluminum plate is a flat plate made of aluminum or aluminum alloy, with the following characteristics:

Material

Pure aluminum plate: made of pure aluminum, with low strength but good corrosion resistance.

Aluminum alloy plate: by adding copper, magnesium, manganese and other elements to improve strength, hardness and other properties.

Thickness

Usually the thickness is between 0.2mm and 500mm, and can be divided into:

Thin plate (0.2mm-6mm)

Medium plate (6mm-25mm)

Thick plate (25mm-200mm)

Ultra-thick plate (more than 200mm)

Surface treatment

Anodizing: improve corrosion resistance and aesthetics.

Coating: such as spraying and electrophoretic coating, increase protection and decorative effects.

Wire drawing: form texture and enhance texture.

Application field

Architecture: used for curtain walls, roofs, etc.

Transportation: used for parts of automobiles, aircraft, and ships.

Electronic appliances: used for radiators, housings, etc.

Packaging: used for food and drug packaging.

Mechanical equipment: used to manufacture parts.

Advantages

Lightweight: low density and light weight.

Corrosion resistance: surface oxide film provides good protection.

Easy to process: strong plasticity, easy to cut, bend, etc.

Thermal conductivity: good thermal and electrical conductivity.

Environmental protection: recyclable and reusable.

Common grades

1 series: pure aluminum, such as 1060, 1100.

3 series: manganese aluminum alloy, such as 3003.

5 series: magnesium aluminum alloy, such as 5052, 5083.

6 series: magnesium silicon aluminum alloy, such as 6061, 6063.

Aluminum sheet is widely used in construction, transportation, electronics, packaging and other fields due to its light weight, corrosion resistance and easy processing.