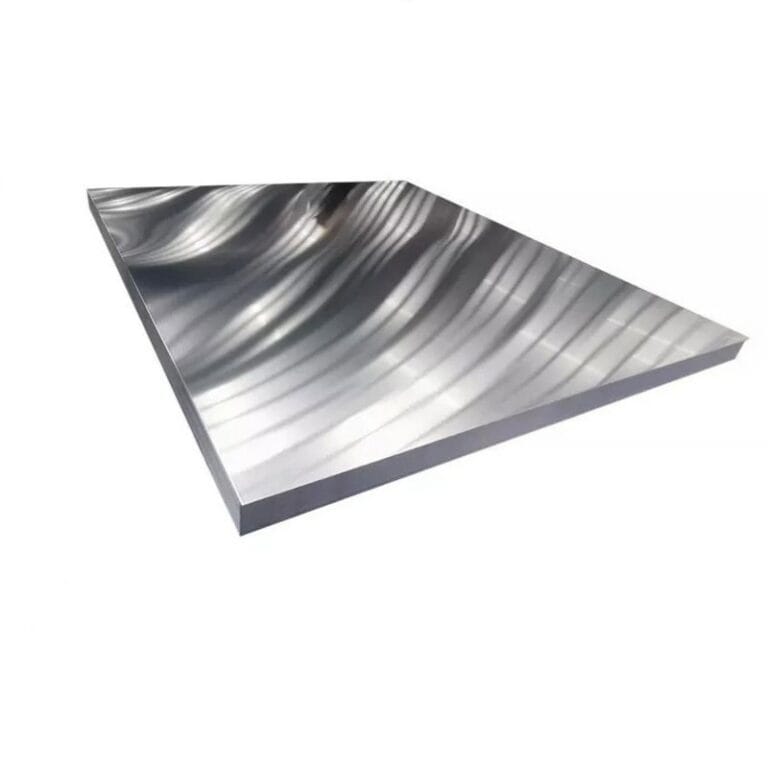

Aluminum coil

Aluminum coil is a common aluminum product, usually made of pure aluminum or aluminum alloy through hot rolling or cold rolling process. It has the characteristics of light weight, corrosion resistance, easy processing, etc., and is widely used in many industries.

Main features

Lightweight: Aluminum has low density, aluminum coil is light, easy to transport and install.

Corrosion resistance: It is easy to form an oxide film on the surface, with good corrosion resistance.

Easy to process: It can be cut, bent, stamped and other processes to meet various needs.

Electrical and thermal conductivity: It has excellent electrical and thermal conductivity and is often used in electronics and heat dissipation fields.

Recyclable: It can be recycled many times, which is environmentally friendly and economical.

Common types

Pure aluminum coil: The purity is higher than 99%, and it is used in occasions with high purity requirements.

Alloy aluminum coil: Other elements (such as manganese and magnesium) are added to improve strength, hardness and other properties.

Coated aluminum coil: The surface is coated with a protective layer to enhance corrosion resistance and aesthetics.

Application areas

Construction: Used for roofs, walls, ceilings, etc.

Transportation: Used in the manufacture of cars, trains, airplanes, etc.

Packaging: Packaging materials for food, medicine, etc.

Electronic appliances: used for heat sinks, capacitors, etc.

Industry: used for chemical equipment, heat exchangers, etc.

Specifications

Thickness: usually 0.2mm to 6mm.

Width: commonly 1000mm to 2000mm.

Length: customized according to demand, usually in coils.

Production process

Melting and casting: melting aluminum ingots and casting them into billets.

Hot rolling: rolling into thicker coils after heating.

Cold rolling: further rolling to achieve the required thickness and surface quality.

Annealing: improve material properties.

Surface treatment: coating or anodizing.

Precautions

Storage: avoid humid and corrosive environments.

Handling: prevent collisions and scratches.

Processing: use appropriate tools to avoid deformation or damage of materials.

Aluminum coils have become an important material in modern industry due to their excellent performance and wide application.