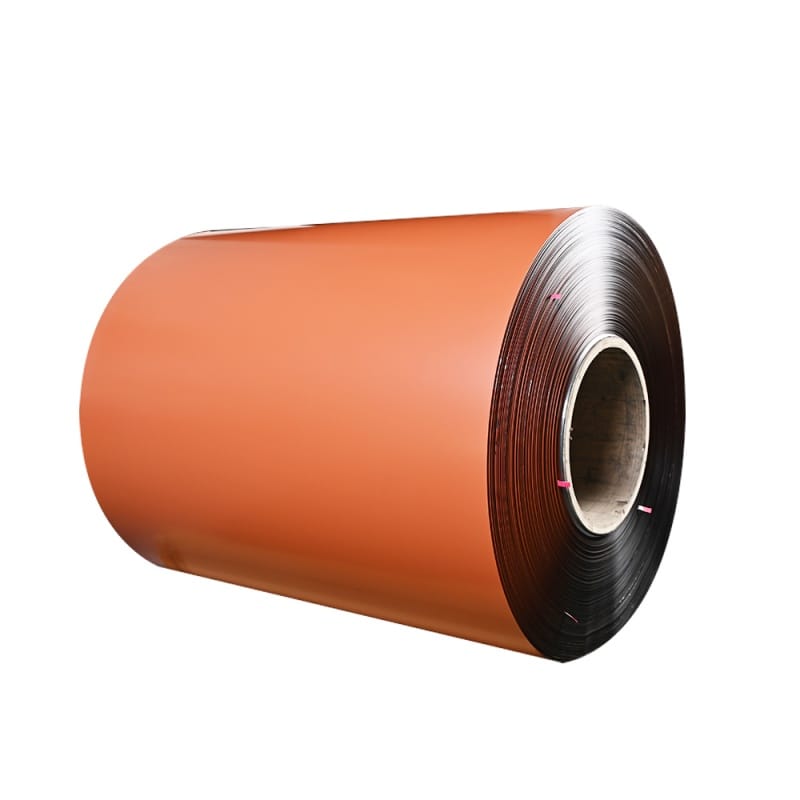

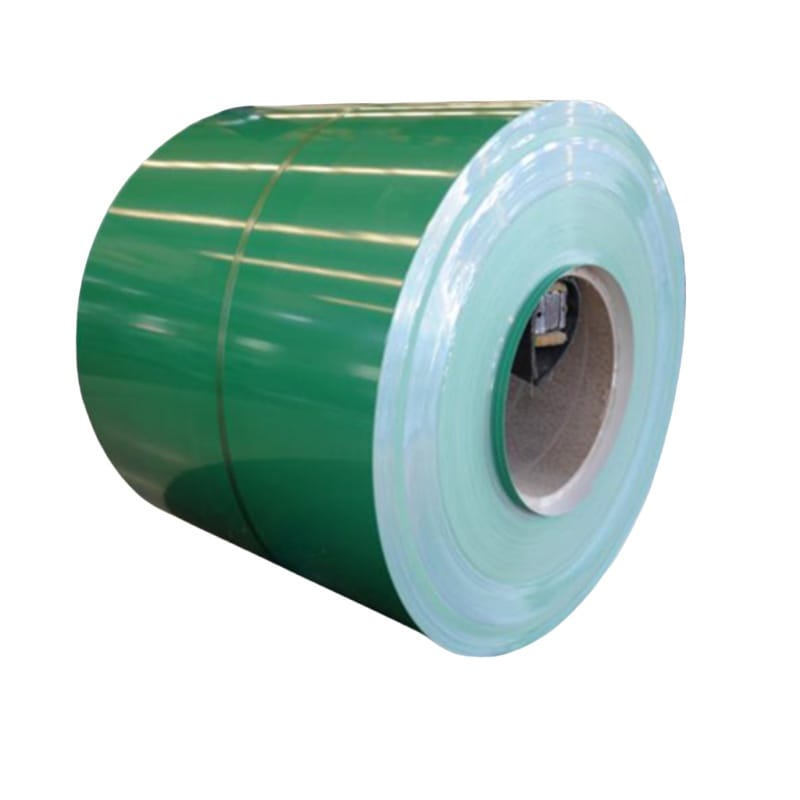

PPGI Steel Coil

Color-coated steel coil refers to a composite material formed by coating an organic coating on the surface of a cold-rolled steel sheet, a galvanized steel sheet or an aluminum-zinc alloy-coated steel sheet and curing it by baking. It not only has the mechanical properties of a steel sheet, but also has the decorative and corrosion resistance of an organic material.

Description

Color-coated steel coil refers to a composite material formed by coating an organic coating on the surface of a cold-rolled steel sheet, a galvanized steel sheet or an aluminum-zinc alloy-coated steel sheet and curing it by baking. It not only has the mechanical properties of a steel sheet, but also has the decorative and corrosion resistance of an organic material.

Classification of color-coated steel coils

By substrate type:

Cold-rolled steel sheet substrate

Galvanized steel sheet substrate

Aluminum-zinc alloy-coated steel sheet substrate

By coating type:

Polyester (PE)

Silicon-modified polyester (SMP)

Polyvinylidene fluoride (PVDF)

High weather-resistant polyester (HDP)

By use:

Color-coated steel coils for construction

Color-coated steel coils for home appliances

Color-coated steel coils for transportation

Processing of color-coated steel coils

Pre-treatment: Clean the surface of the substrate, remove oil and oxides, and ensure the adhesion of the coating.

Coating: Apply the coating evenly to the surface of the substrate by roller coating or spraying.

Baking: Curing the coating at high temperature to form a strong coating.

Cooling: Cooling after baking to ensure stable coating performance.

Post-treatment: Embossing, lamination and other treatments as needed.

Characteristics of color-coated steel coils

Corrosion resistance: The coating effectively isolates the corrosive medium and prolongs the service life.

Decorativeness: A variety of colors and textures are available to meet different decorative needs.

Mechanical properties: Maintain the strength, hardness and ductility of the steel plate.

Weather resistance: The special coating can resist environmental erosion such as ultraviolet rays and acid rain.

Processability: Easy to cut, bend, stamp and other processing.

Uses of color-coated steel coils

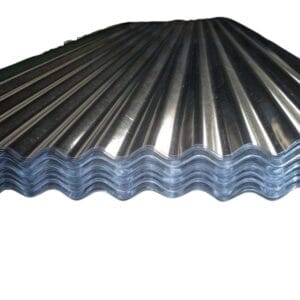

Construction field: Used for roofs, walls, partitions, etc., with both aesthetics and protective functions.

Home appliance field: Used for the outer shells of refrigerators, washing machines, air conditioners, etc., to provide protection and decoration.

Transportation: Used for interior and exterior decoration and protection of cars, trains, and ships.

Furniture field: Used for office furniture, cabinets, etc., to provide a durable and beautiful surface.

Other fields: Such as billboards, containers, etc., to meet diverse needs.

Color-coated steel coils are widely used in many fields such as construction, home appliances, and transportation due to their excellent performance and diverse applications. Its corrosion resistance, strong decorative properties and good mechanical properties make it an indispensable material in modern industry and construction.