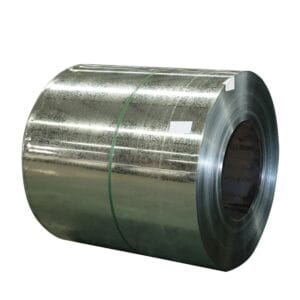

Galvanized Steel Coil

Galvanized steel coil is a product made by galvanizing cold-rolled or hot-rolled steel coil, and the surface is covered with a layer of zinc to improve corrosion resistance. There are two main galvanizing methods: hot-dip galvanizing and electro-galvanizing.

Description

Galvanized steel coil is a product made by galvanizing cold-rolled or hot-rolled steel coil, and the surface is covered with a layer of zinc to improve corrosion resistance. There are two main galvanizing methods: hot-dip galvanizing and electro-galvanizing.

Classification

Classification by galvanizing process:

Hot-dip galvanized steel coil: The steel coil is immersed in molten zinc liquid to form a thicker zinc layer with strong corrosion resistance.

Electro-galvanized steel coil: A thinner zinc layer is plated on the surface of the steel coil through an electrolytic process, and the surface is smoother and suitable for precision processing.

Classification by substrate:

Cold-rolled substrate galvanized steel coil: The substrate is cold-rolled steel plate, with a smooth surface and high dimensional accuracy.

Hot-rolled substrate galvanized steel coil: The substrate is hot-rolled steel plate, with a rougher surface and high strength.

Classification by zinc layer thickness:

Conventional galvanized steel coil: The zinc layer thickness is moderate, suitable for general use.

Thick zinc layer galvanized steel coil: The zinc layer is thicker, with stronger corrosion resistance, suitable for harsh environments.

Classification by surface treatment:

Ordinary galvanized steel coil: The surface is a zinc layer without additional treatment.

Color-coated galvanized steel coil: A color coating is applied on the galvanized layer, which is both beautiful and corrosion-resistant.

Process

Hot-dip galvanizing process:

Degreasing and cleaning: Remove oil and impurities on the surface of the steel coil.

Annealing treatment: Improve the plasticity and toughness of the steel coil.

Zinc immersion treatment: Immerse the steel coil in molten zinc liquid to form a zinc layer.

Cooling treatment: After cooling, a uniform zinc layer is formed.

Electrogalvanizing process:

Electrolytic cleaning: Remove oxides and impurities on the surface of the steel coil by electrolysis.

Electroplating treatment: Electrolytically deposit a layer of zinc on the surface of the steel coil.

Post-treatment: Passivation or oiling treatment is performed to improve corrosion resistance.

Color coating process:

Primer, topcoat and varnish are applied to the surface of the galvanized steel coil, and a color coating is formed after baking and curing.

Features

Strong corrosion resistance: The zinc layer effectively isolates air and moisture to prevent steel from rusting.

Long service life: The galvanized layer can significantly extend the service life of steel.

Good surface quality: The surface of galvanized steel coil is smooth and suitable for subsequent processing.

Low cost: Compared with materials such as stainless steel, galvanized steel coil has high cost performance.

Environmental protection: The galvanized layer can be recycled and meets environmental protection requirements.

Uses

Construction industry:

Used for roofs, walls, steel structures, etc.

Make ventilation ducts, drainage systems, etc.

Home appliance manufacturing:

Used for the outer shell and internal structure of home appliances such as refrigerators, washing machines, and air conditioners.

Automotive industry:

Used for body parts, chassis, fuel tanks, etc.

Power equipment:

Used for cable trays, distribution boxes, transformer housings, etc.

Agricultural field:

Used for greenhouses, granaries, agricultural machinery and equipment, etc.

Furniture manufacturing:

Used for office furniture, lockers, shelves, etc.

Galvanized steel coils are widely used in construction, home appliances, automobiles, electricity, etc. due to their excellent corrosion resistance, good processing performance and low cost. According to specific needs, galvanized steel coils with different galvanizing processes, zinc layer thickness and surface treatment can be selected.